Wilhelm T & P is the right contact for consultation on systems in the plastics processing industry. We have been working with leading international machine manufacturers for decades. This allows us to guarantee our customers the best quality and reliable service. We have been representing company Saurer successfully since 1987.

The Saurer Group, founded in 1853, is a leading, globally active technology company with a focus on machines and components for yarn production. Today, the group is a solution provider for the textile industry consisting of two segments. Spinning Solutions offers high-quality, technologically advanced and customer-specific automated solutions for staple fibre processing from bale to yarn. Saurer Technologies specialises in intelligent and economical twisting and cabling machines for tire cord, carpet, staple fibre, glass filament and industrial yarns, which allow customers to adapt flexibly to dynamic market requirements. Automation Solutions provides textile mills with an array of labour-saving systems.

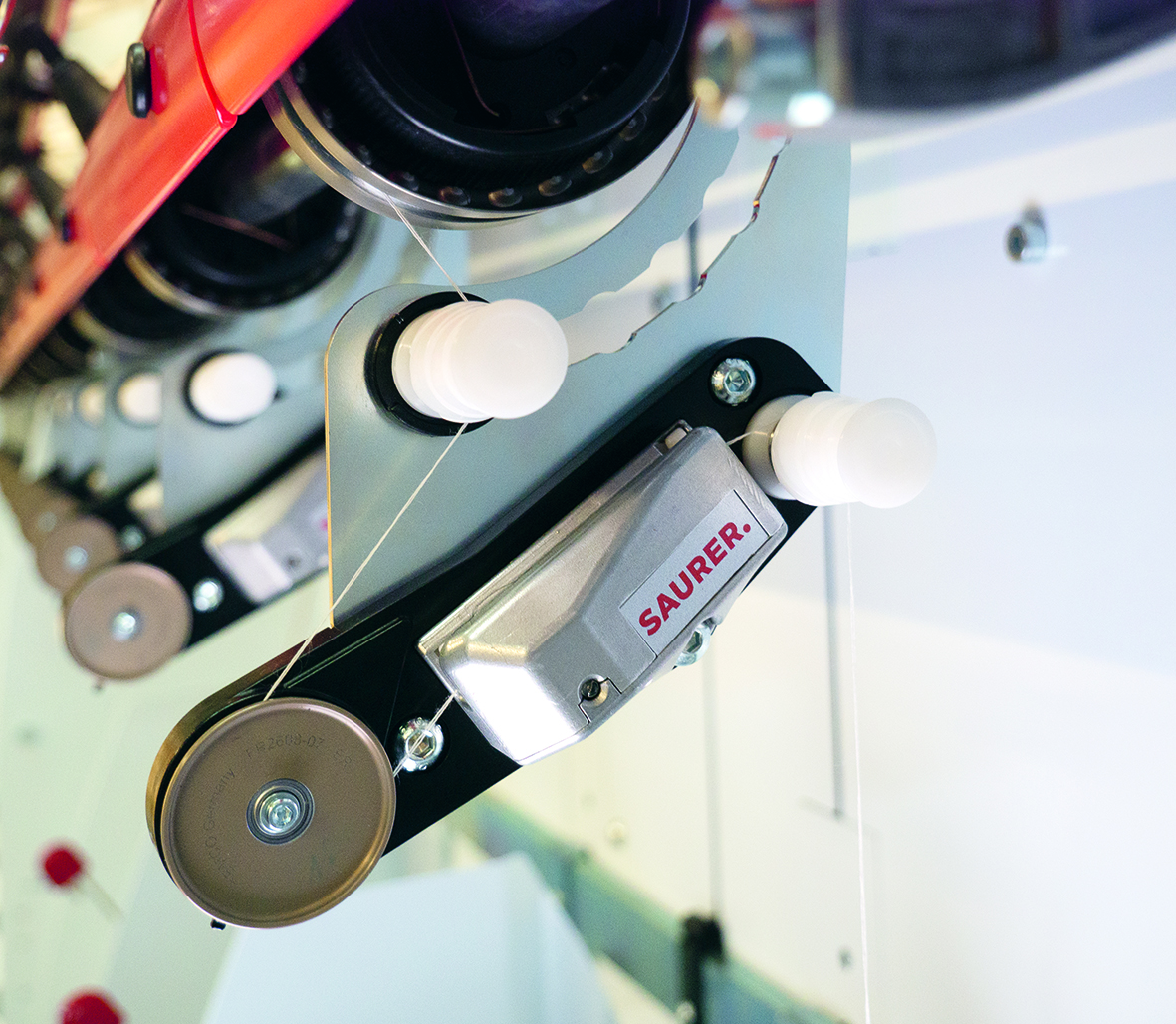

Quality sensor

Our latest generation of quality sensor takes the testing of your yarn to a new level. By combining intelligent software and innovative evalution technology, the new quality sensor generates the best possible results for your yarn quality.

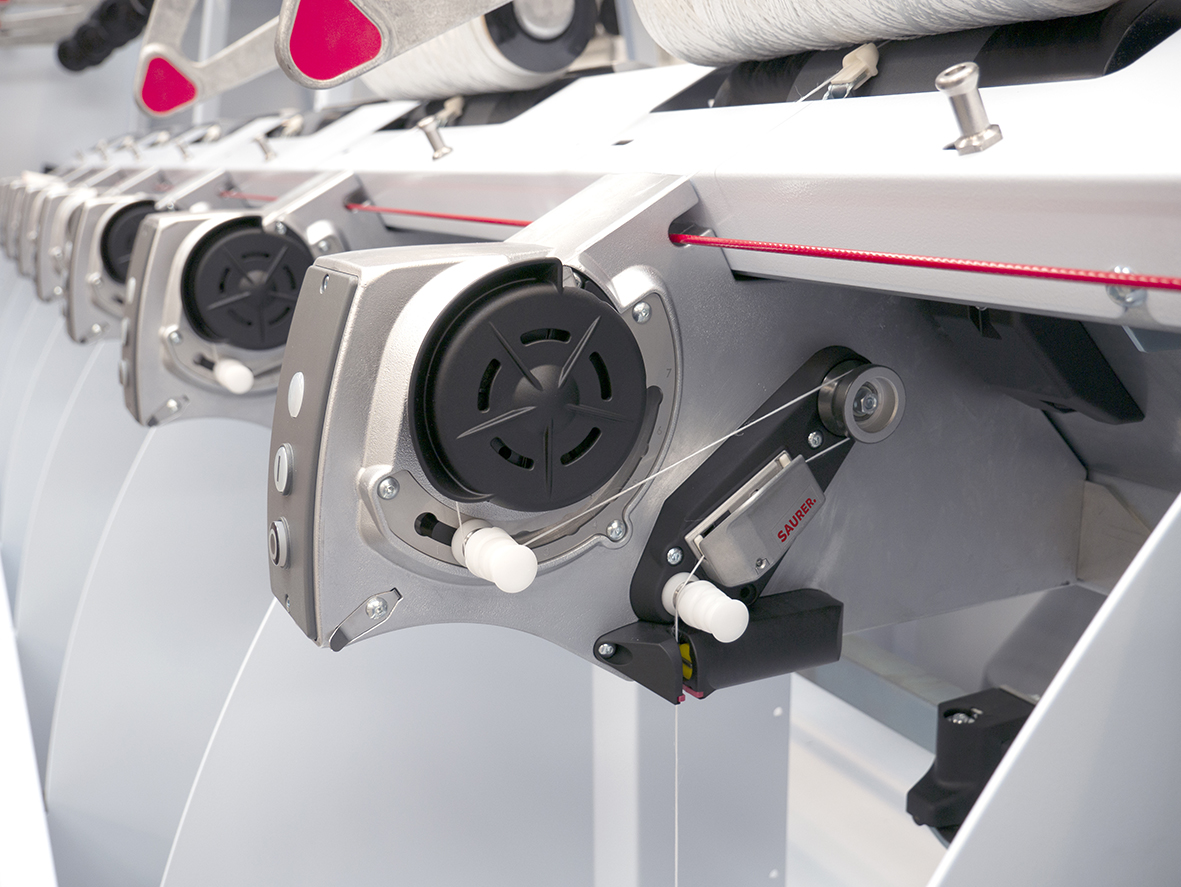

Central adjustment of the yarn balloon guide and deflection roller

The yarn guide rollers used to influence the takeup tension can be centrally adjusted side by side.

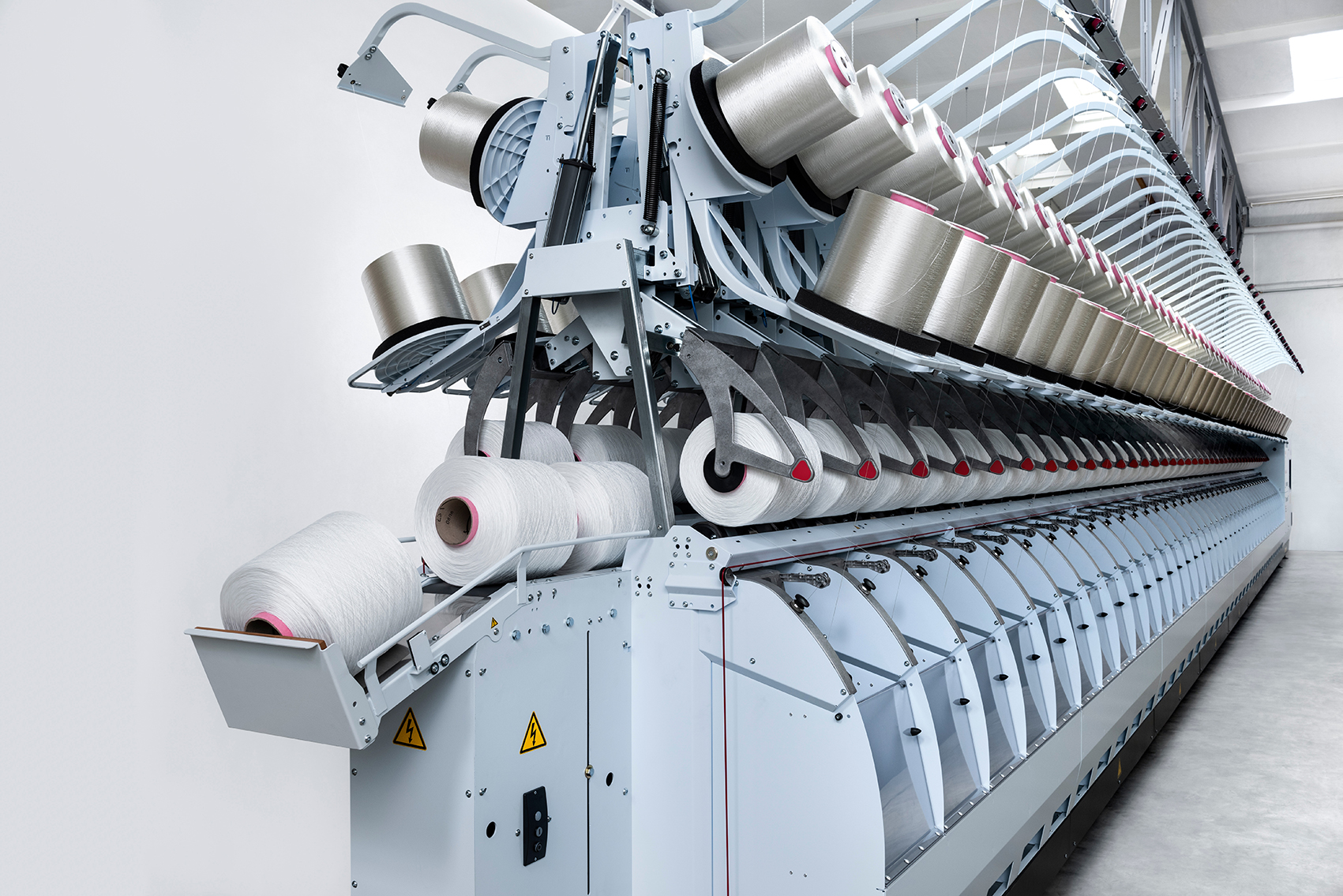

CompactTwister

The CompactTwister has been established in the market for over 25 years. The latest generation, the series 8, once again sets new standards for the quality of twisted yarn, flexibility, energy consumption, robustness, lower space requirement and ease of maintenance.

Nearly 5 million supplied spindles demonstrate its leading position on the market. Thanks to innovative development and the latest production methods, the CompactTwister offers high efficiency combined with excellent quality of the cross-wound delivery packages produced.

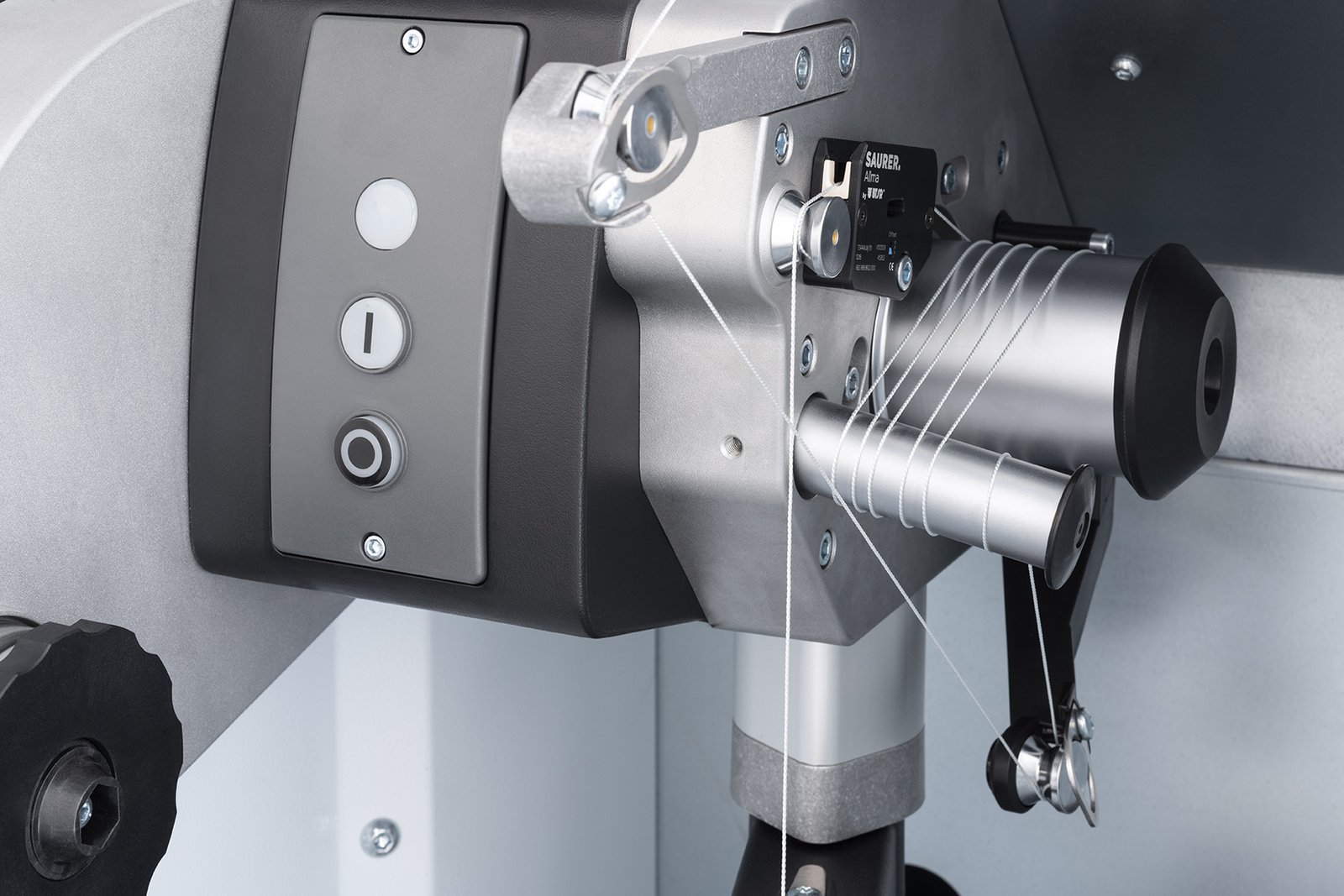

CableCorder CC5 – Cabling in pole position

The CableCorder CC5 marks what is now the fifth generation of successful direct cabling machines for tire cord and technical yarns from our company. With numerous innovations, it once again demonstrates its technological leadership and the associated customer benefits.

Our customers benefit economically from a coherent overall package consisting of a smart spindle concept, modern quality monitoring, improved ergonomics and both individual and flexible solutions for automation and data management.

The CableCorder CC5 is available as "3PLY" variant for producing symmetrical 3-ply tire cord. The customers benefit from the machine's high cost-effectiveness and simple handling. We offer the "TFO" variant for processing yarns in the two-for-one twisting process. The main advantage here is the high delivery speed of up to 150 m/min.

Tire cord is rightly expected to meet the highest standards, because it must be extremely resilient and guarantee the best possible safety. Online monitoring of the quality parameters with our newly developed quality sensor reliably ensures the required quality.

CarpetCabler

For over 35 years, CarpetTwister and CarpetCabler have been producing premium yarns for high-quality carpets and other textiles using their twisting and cabling machines. Throughout the decades, there has been a common thread of innovative developments, the use of the latest technologies, and a willingness to go the extra mile with their customers.

Their new Series 1.10 offers a maximum range of possibilities to reliably and competently meet even the most demanding requirements of the dynamic market.

Control panel (human-machine interface)

The new control panel with multitouch technology and the innovative user interface makes operation even more intuitive and easier.

Overfeed roller

Depending on the wrap-around angle, the pre-take-up roller reduces the balloon tension to the desired take-up tension. The overfeed covers enable safe working and additionally carry the yarn clamp and the storage pin for easy intermediate storage of unwinding aids.